Overview

≪Summary≫

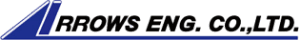

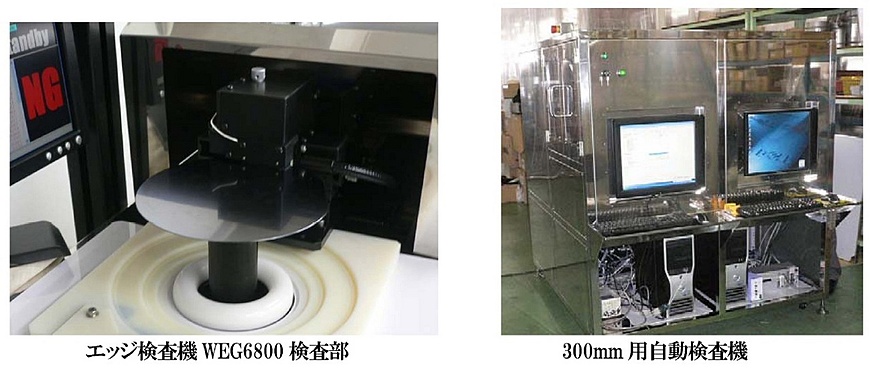

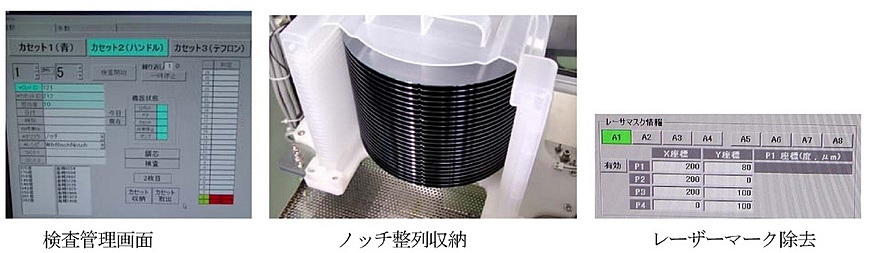

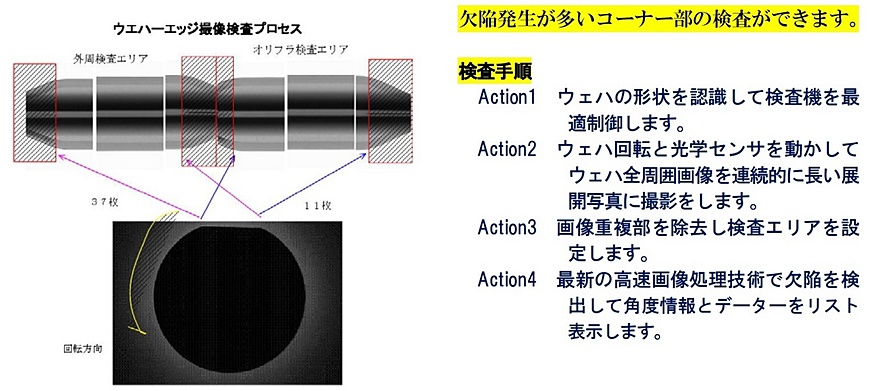

This is a cassette-to-cassette type wafer edge automatic inspection machine. Achieves a high throughput of 10 seconds for inspection and 30 seconds for one cycle. The robot takes out the wafers one by one from the 25-sheet storage cassette, inspects them after automatic alignment, and stores them in the cassette. Easy to operate.

Automatic defect inspection such as scratches, foreign substances, chips, and cracks is possible.

High-speed inspection of 30 seconds per sheet including transportation time.

It is a high-precision inspection machine that is easier to use by adding new functions.

Compact and power saving design. AC100V 8A

External dimensions w1200 × d900 × h1600mm Weight 160kg

Just set the cassette and push the operation button, the robot takes out the wafers one by one and carries them to the inspection station. After centering the image, the edge of the wafer periphery and the top and bottom three surfaces are simultaneously photographed and inspected for defects such as scratches, foreign particles, cracks, and chips and returned to the cassette.

The inspection is a wafer backside suction type, and the camera discriminates the notch/orientation flat for optimum control.

Features/functions

≪Characteristics≫

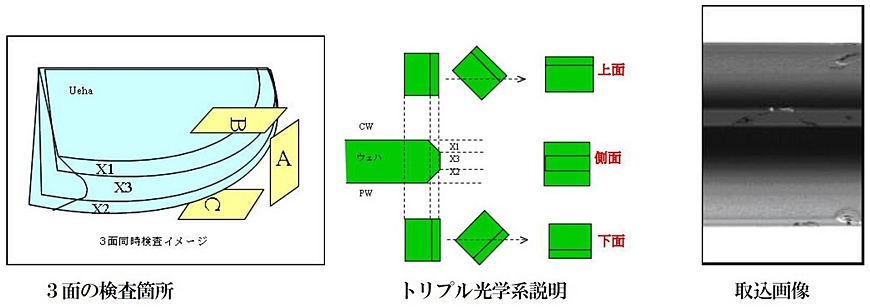

1. Simultaneous imaging of the three edges, imaging of the entire circumference of the wafer and defect inspection are possible.

2. Triple optical system allows one line camera to perform three-sided inspection.

3. Integrated lighting has realized the optimum lighting for edge inspection.

4. Appearance inspection including orientation flat/notch is possible. (The notch is an inspection of the bevel surface only)

5. High performance with a measurement resolution of 10 μm, a detection defect size of 20 μm, and a pass/fail judgment defect of 50 μm.

≪Function≫

≪Function≫

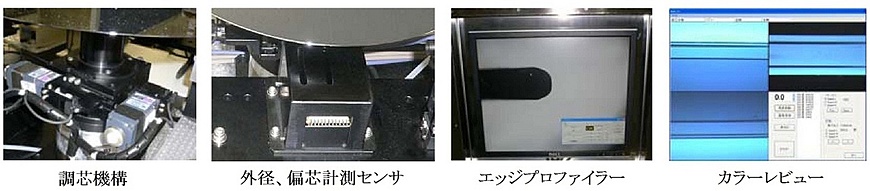

1. Automatic alignment mechanism: Automatically aligns the wafer center with the inspection center on the image.

2. 3 -sided independent setting: Recipe of inspection condition and lighting can be set.

3. Re-inspection function: NG judgment wafer can be visually re-inspected.

4. Display change function: The magnifying and reversing functions make it easier to see the raw image.

5. Large dirt and markings can be separated from defects.

Inspection point

The edge A, top B, and bottom C of the wafer are simultaneously imaged. Since the bevel surface can be inspected from both sides with the triple optical system, it is possible to inspect defects that cross the boundary.

Lighting/edge inspection

Two LED integrated lights for edge inspection and fiber lights for chip detection are attached as standard.

Optional features

<<Related products>>

Related products